This is the damaged swingarm. The cracks are very obvious and the location is consistent with the fact that a gusset can create a stress riser. The top connecting tube is also the part that contacted the frame on bottom out and served as a fulcrum.

Another view of the crack from the underside.

To make sleeves for the 3/4" tubing I used 7/8" tubing with a 0.065" wall thickness. This means that the inside sleeve diameter is 0.005" smaller than the tubing that it is repairing. I made the long milled out channel to allow both the sleeve to expand to fit the original tube and to give a welder enough room to run two passes of TIG to secure the sleeves.

Here the sleeves are ready for welding

With the sleeves welded into place their appearance lent to the nickname "Socks".

The bike was performing really well with the "Socks" welded in place; swingarm stiffness had improved and the travel configuration change helped match the spring weight to my still lingering winter weight.

Then I noticed the scratch while hanging the bike on the chairlift. Shown here circled and pointed to, you can see why it took some time to decide if this might just be a scratch instead of a crack.

The main cause for concern was the location of the scratch or crack and that it radiated outwards (or towards) the weld at the corner of the gusset. On review it seems that this was a scratch that occurred when I was holding the gussets in place for tack-welding with the swing arm in-situ. The swing arm was removed from the prototype before completing the TIG welding

I made gussets while the debate between crack or scratch was unresolved.

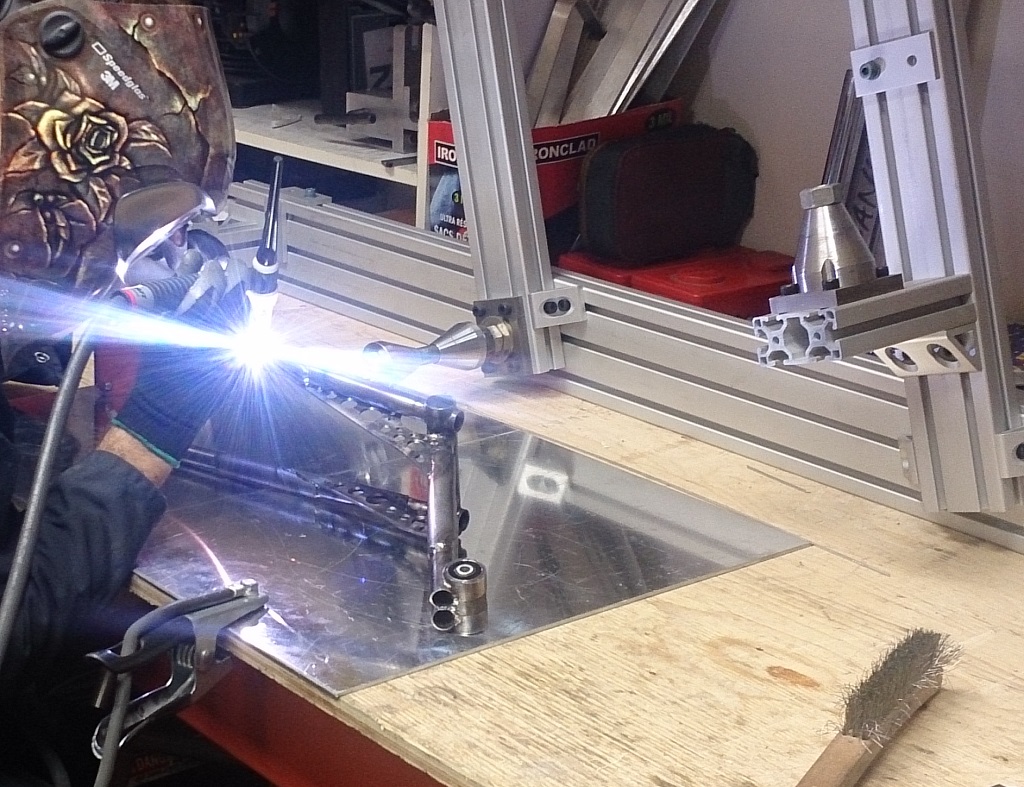

I got to watch [MY PRIMARY WELDER] TIG the gussets in place AND ask questions.